Mcdonnell miller air flow switches sense air flow or no air flow by responding only to velocity of air movement. They provide a positive and economical way to detect change or loss of air flow velocity caused by closed damper or fan inlet a loose fan wheel a slipped or broken fan belt a dirty or clogged filter or an overload on a fan motor switch.

Download 1967 Vw Karmann Ghia Wiring Diagram

Mcdonnell miller 150 wiring diagram. Maximum pressure150 psi 105 kgcm2 settings and differential pressures values are 8 32mm. 1 table of contents ps 800 series 5 pse 800 series 5 4242a and 18 42s42s a 93193 20 94194 22 150157 150s157s 24 1575 29. 116 basic wiring mcdonnell miller 14. We are committed to ensuring that the individuals whose details we hold understand our privacy practices. Boiler controls parts mm 701e series 150 150s 157 157s pages 24 28. Mcdonnell miller s warranty is one 1 year from date.

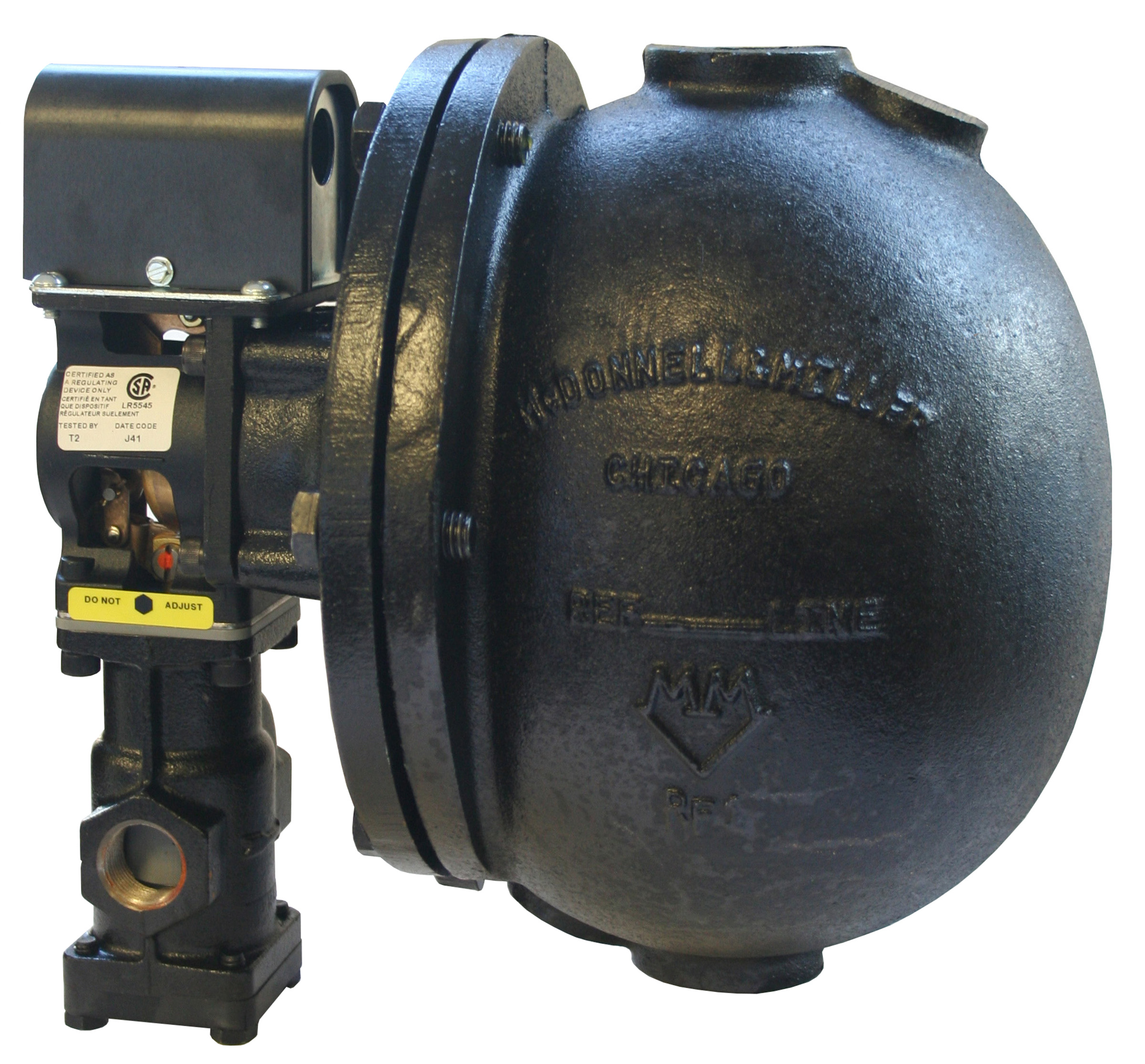

Mcdonnell miller is a leader in engineering and manufacturing boiler controls liquid level controls low water cutoffs and flow switches for steam and hot water boilers in industrial commercial and building trades applications. Switches and how to wire popular mcdonnell miller p r o d u c t s. Wiring diagrams for motorized valves refer to the valve manufacturers wiring instructions. Itt controls also supplies products and components made by mcdonnell miller. Mcdonnell and miller are now part of itt. Following the appropriate wiring diagram refer to page 11 based on your application requirements and using bx armored cable or thinwall electrical metal tubing connector fittings make electrical connections to the junction box l.

Mcdonnell miller service parts catalog parts list mm 701b. Many mcdonnell miller products are used to switch electrical circuits in response to physical parameters such as level and flow. Mcdonnell miller products are used for demanding applications in the oil and gas industry where high accuracy is required. Step 4 electrical wiring to prevent a fire do not use this product to switch currents over 74a 13 hp at 120 vac or 37a 13 hp at 240. Main line switch. Understanding electrical wiring is necessary to ensure proper installation and operation.

There must be a minimum space of 2 13mm between connector fittings and electrical live metal. Pneumatic valves or relays valves can be used in hazardous and non hazardous process systems. Therefore we are providing you with this basic wiring section as primary information on electric circuits and. Flow switch replacement parts notes notes. Wiring diagrams for motorized valves refer to the valve manufacturers wiring instructions. Mcdonnell miller s warranty is one 1 year from date.

Pa r a l l e l warning to prevent an electrical fire equipment damage or electrocution follow electrical wiring instructions codes and ordinances. Failure to follow this warning could cause property damage personal injury or death. In particular we want to make sure that we are respectful of your data protection preferences and that you understand your data privacy rights. Low water cut off only 1.