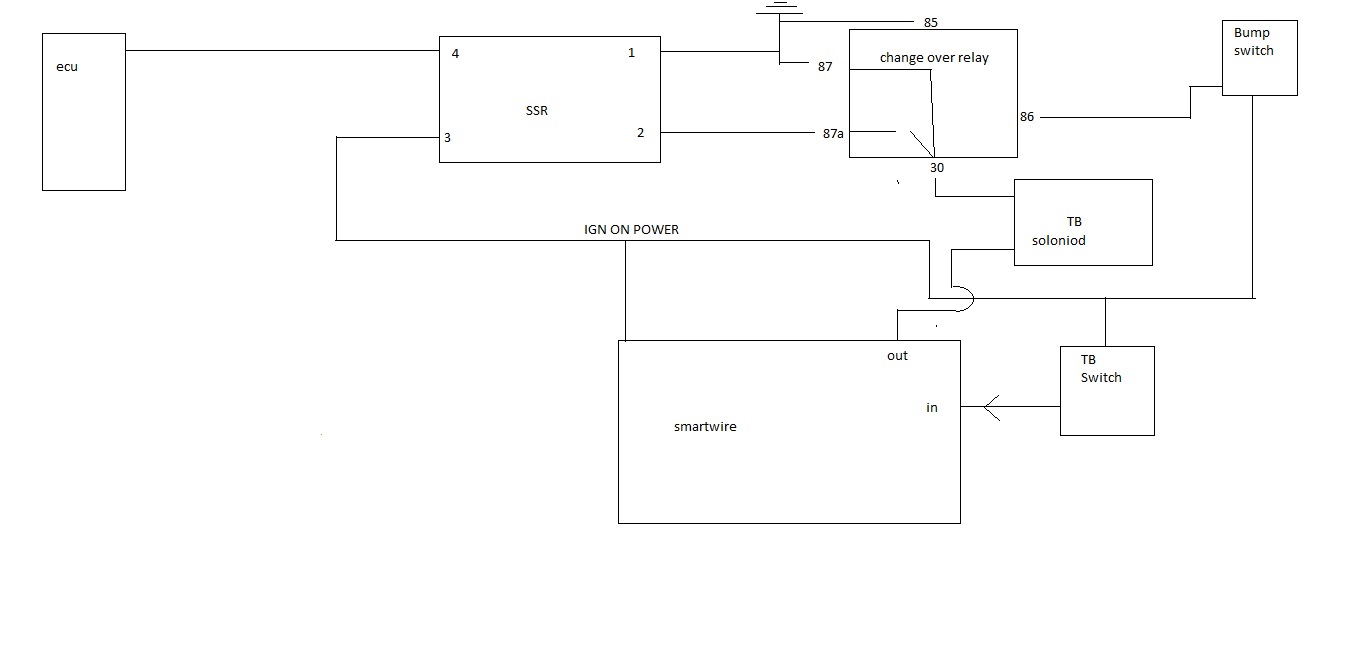

Mount relay on firewall of engine compartment using a sheet metal screw. From connectors and pins to wire loom and tools.

Power Tap Connector

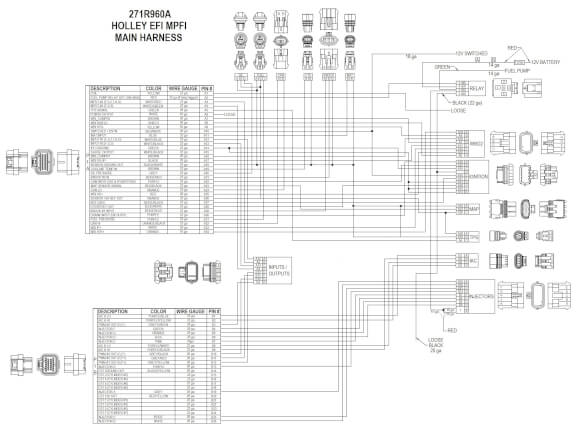

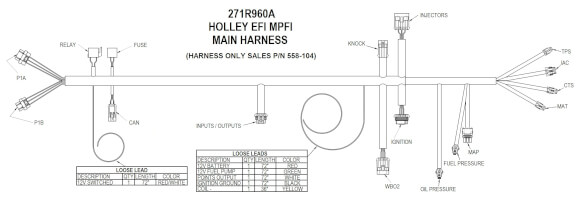

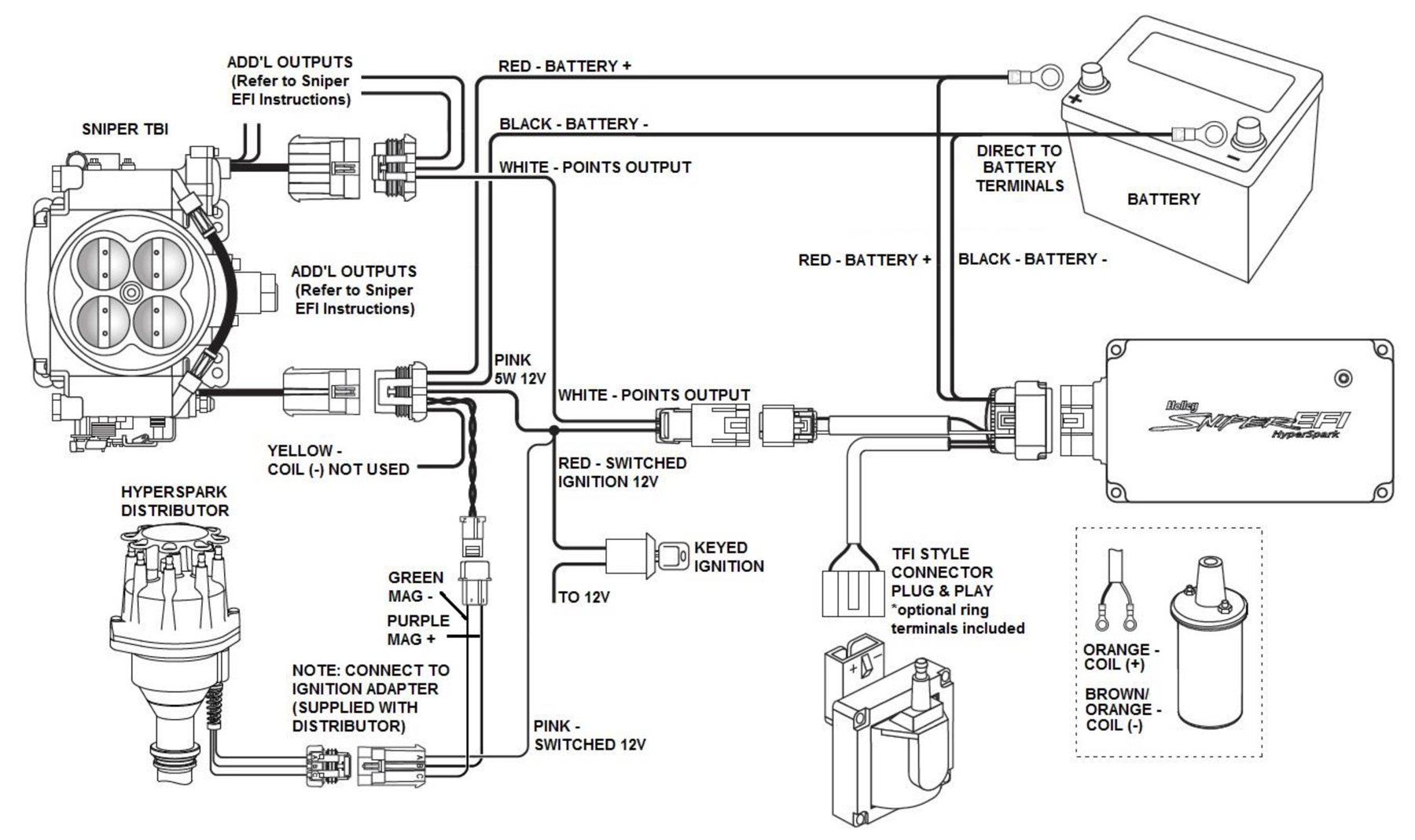

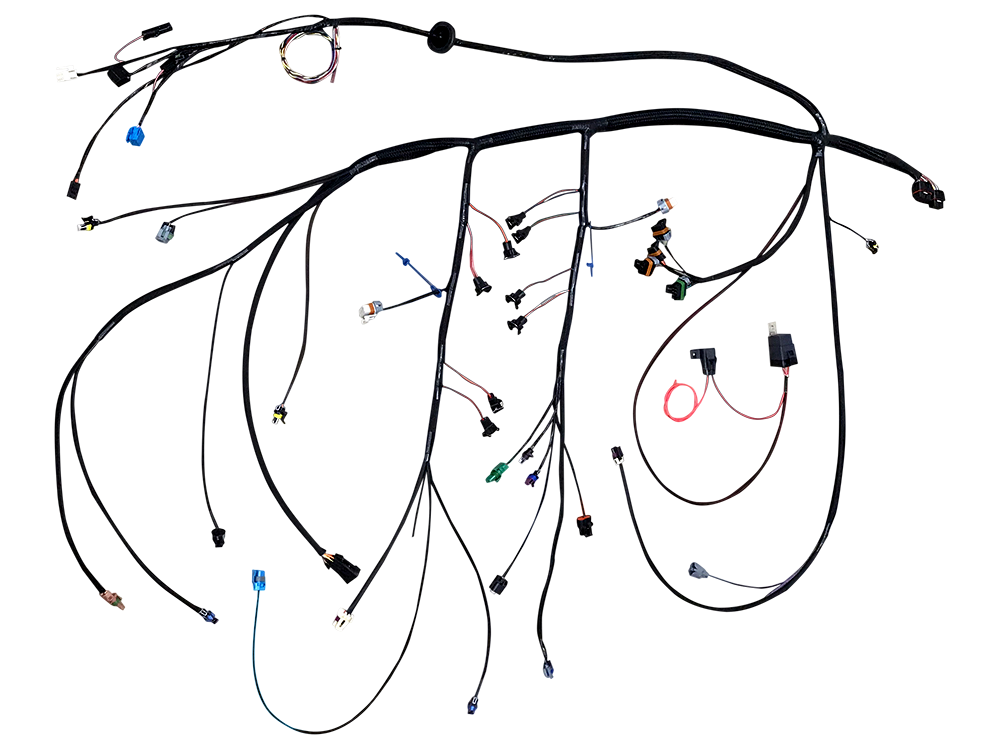

Holley power tap wiring diagram. 3 11 important wiring dos and donts. Holley performance products has written this manual for the installation of the pro jection 4d and 4di fuel injection system. We have one goal to provide you a one stop solution for all of your wiring components needs. Introducing the holley efi wiring shop. Black nylon braided wire loom from 18 to 2 and every connector pinssealstpa included we utilize on our main harnesses are now. This manual contains all the information needed to install this system.

This manual contains information and diagrams related to wiring most holley efi products including ecus ignition systems nitrous systems watermethanol injection systems sensors and more. Each holley efi connector that has 0 5v inputs has its own 5 volt reference voltage output and sensor ground. Before punching or drilling a hole in the firewall make sure you know what is on the other side. You will need holley fuel pump relay kit pn 12 753 or equivalent 4 wire relay. Featuring items from multiple holley brands the wiring shop is your one stop place for everything needed to work on your aftermarket fuel injection or high performance ignition system. We have everything you need to build or service your holley efi powered machine.

Please read all the warnings notes and tips as they contain valuable information that can save you time and money. Wiring the fuel pump with a relay. Disconnect the cables from the battery. All 0 5v sensors require a 5 volt reference voltage and a sensor ground. Whether youre building a harness from scratch replacing an old connector or installing a new sensor holleys wiring shop has the tools and equipment you need. These need to be properly wired to each 0 5v sensor used.

Wire the signal output wire from a 0 5v sensor to the appropriate pin using the holley wiring diagram.