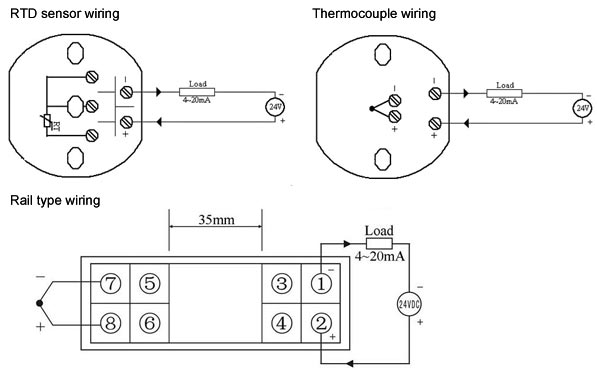

The following connection diagrams illustrate how to connect various rtd types to your daq device. 4 wire circuits may be usable over a longer distance than 3 wire but you should consider using a transmitter in electrically noisy environments.

Ox 0003 Wire Rtd Wiring A 4 Wire Rtd Schematic Wiring

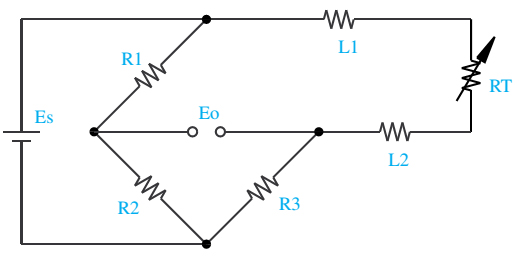

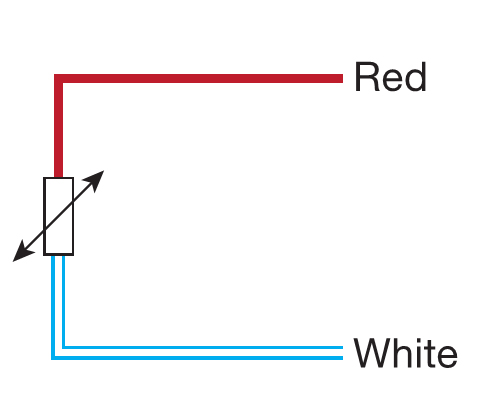

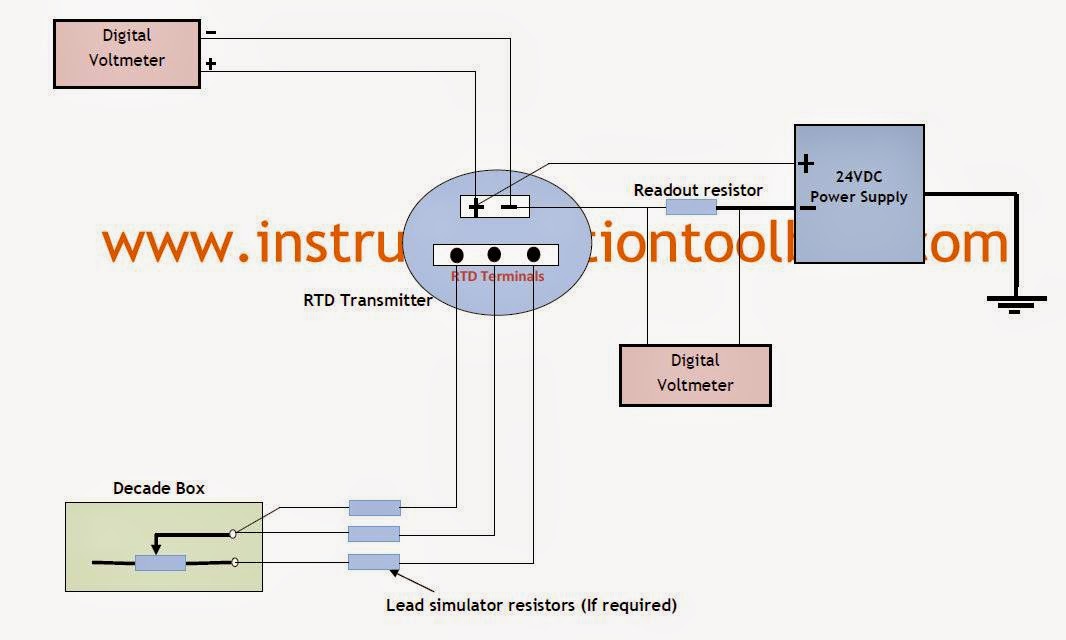

Rtd transmitter wiring diagram. Red red white white red red white red red white black black yellow. Single element 3 wire single element 4 wire dual element 3 wire. A 2 wire rtd configuration is the most useful with high resistance sensors or in applications where a great deal of accuracy is not required. Note to configure a single element 4 wire rtd as a 3 wire system connect only one white lead. Is drives a precise measuring current through l1 and l4. Rtd lead wire configuration per iec 60751.

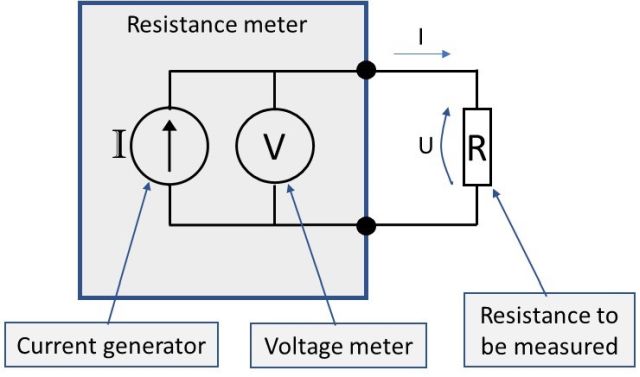

3 wire rtd connections the 3 wire rtd configuration is the most commonly used rtd circuit design and can be seen in industrial process and monitoring applications. When wiring with two wires first jumper across a1 and b1and a2 and b2 respectively then connect pt100 sensors and to the rtd module according to the following diagram on the left. Eo must have high impedance to prevent current flow in the potential leads. 4 wire rtd signal connection connect each of the red leads on the positive side of the resistive element to the excitation positive and channel positive on the daq device. A1b1 a2b2 and c1c2. L2 and l3 measure the voltage drop across the rtd element.

2 wiring diagram for rtds. A resistance temperature detector rtd is a temperature measurement device that accurately uses resistance to measure temperature. Learn the differences between 2 wire 3 wire and 4 wire rtds. Connect the black or white lead on the negative side for the resistive. There are 2 wiring methods for the rtd module and pt100 temperature sensors two wire and three wire connections.