36 volt 500 watt. Current limiting feature helps prevent controller and motor damage due to over current conditions.

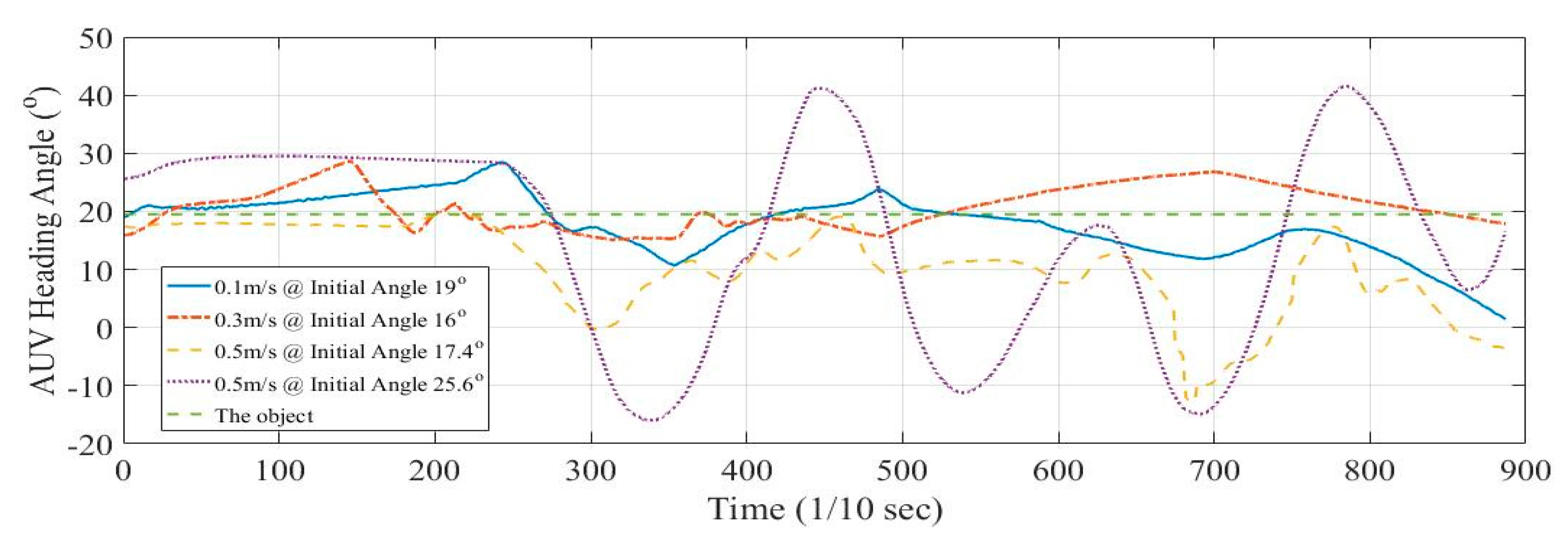

Stator Current With Pso Pid Controller In Dtc Download

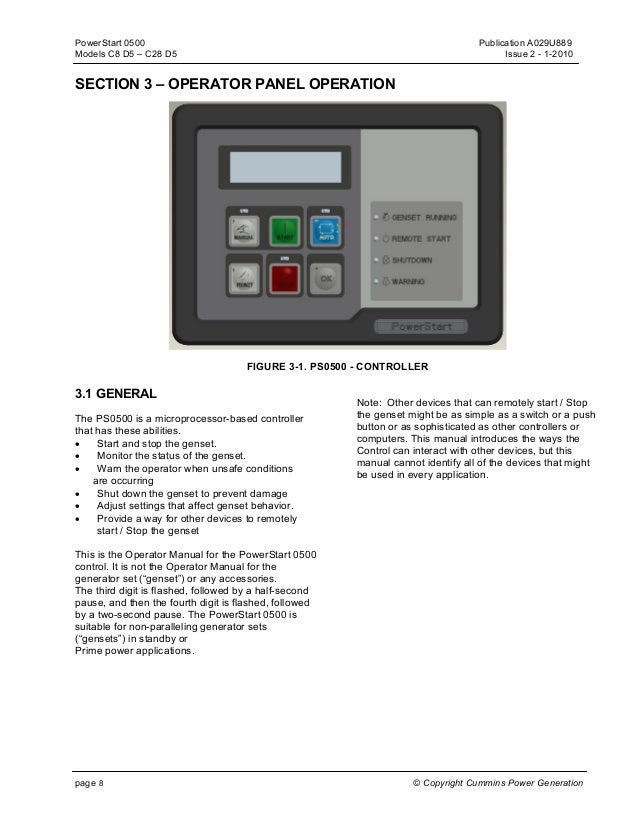

Pso 500 controller wiring diagram. Under voltage protection 31 volts. The control provides a simple operator interface to the generator set manual and remote startstop control and shutdown fault indication. The blue wire carries the brake controller output. 120896 5900 x 24vdc fail secure strike. 120897 5900 x 12vdc fail safe strike. If the control does not respond to the simulator the control or the harness is bad.

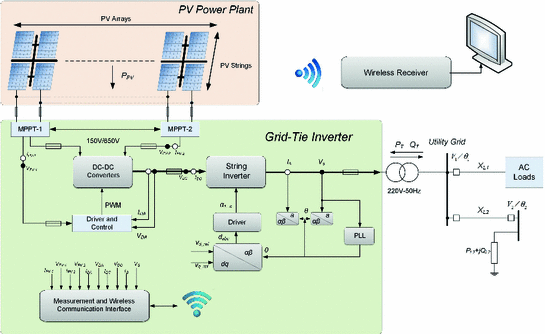

120899 5900 x rf. Generator set control powerstart 0500 description the powerstart control is a microprocessor based generator set monitoring and control system. Pin harness wiring diagram 3 pin. Get contact details and address id. 120902 5900 x corbin russwin m97 m92 to shunt wall plates. 4 pin harness wiring diagram january 1 2002 lit.

Installation and operation manual slc 500 fixed hardware style cat. If the control still doesnt display an oil pressure while cranking the oil pump may be bad. Maximum current 25 amps. I need a wiring diagram for a powerstop 500 ps brake controller. The integration of all control functions into a. 120900 5900 x 24vdc mag lock.

Under voltage protection feature helps prevent over discharge and. Om sai motor parts accessories offering cummins pso 500 generator controller in hyderabad telangana. Start by adding the connection in the wiring diagram below. 120898 5900 x 12vdc fail secure strike. If the control does not respond to the simulator go to next step. 1747 l20 1747 l30 and 1747 l40 processors allen bradley.

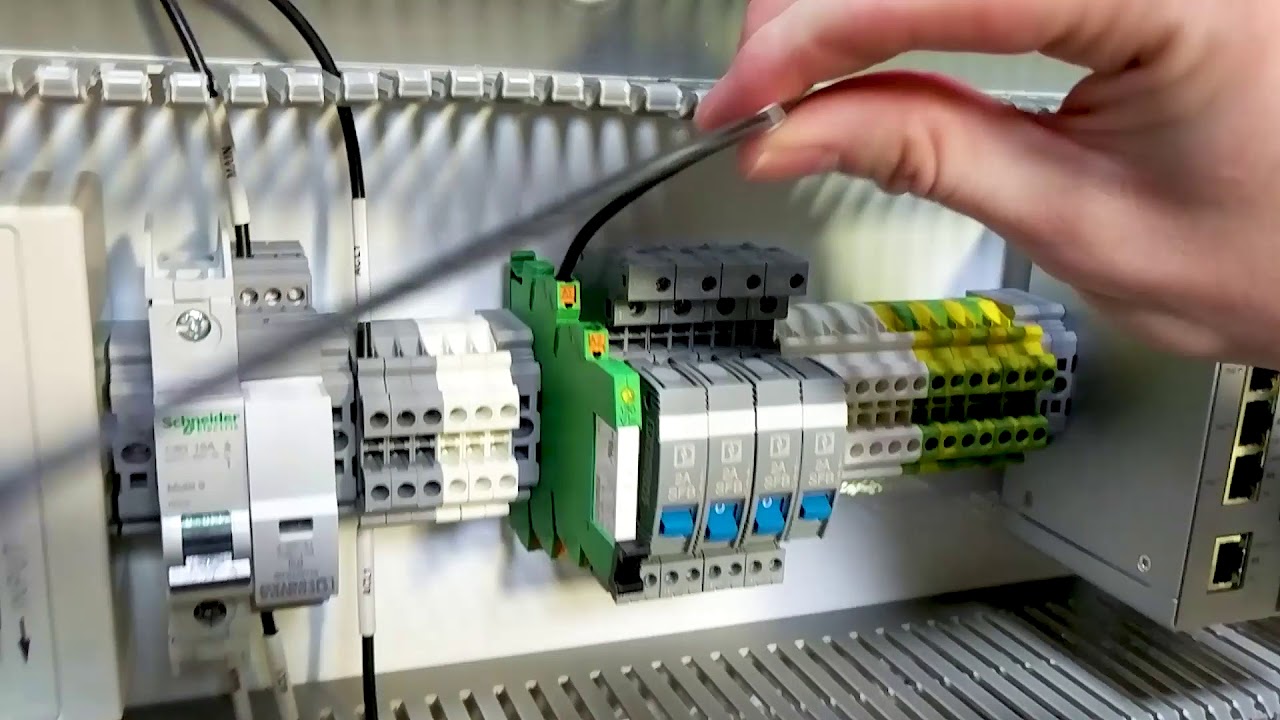

36v 500w speed controller designed for 36 volt motors up to 500 watts. Operating the spreader onoff control starting and stopping the motor note. The ac1 and ac2 terminals should connect to 120vac 50 or 60 hz. Check the resistance in p16 9 and p16 11 sensor comm. Im putting it on a 1996 ford f 150 4 wheel drive posted by wesley peters on jan 07 2020. 120901 5900 x 12vdc mag lock.

The truck ignition must be on to start the warning spreader. The green wire from the controller attaches to the cold side of the brake stoplight switch the white ground wire attaches to the negative battery terminal the red wire supplies 12 volt power to the controller and attaches to the positive battery terminal. This is the simplest way to connect the cnc spindle control upgrade kit and have it operate. Before starting the motor be sure all personnel and equipment are clear of the discharge area. Refer to the engine service manual. Get best price and read about company.

120903 5900 x yale g and b to shunt wall plates. This will ensure that new parts are installed and working correctly. 120895 5900 x 24vdc fail safe strike.