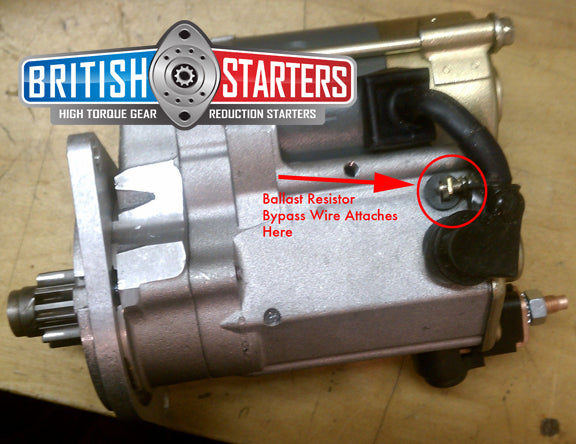

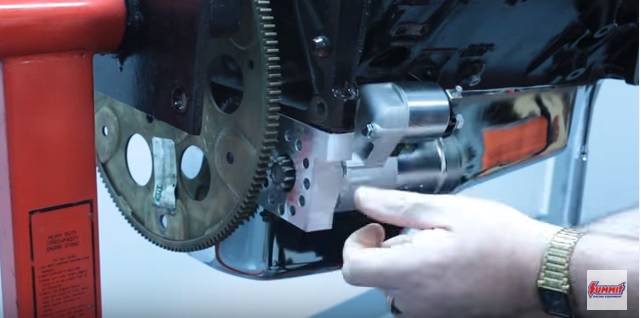

High torque gear reduction starter. 1 round nose shim.

Video Installation Tips For Mini High Torque Starters On Gm

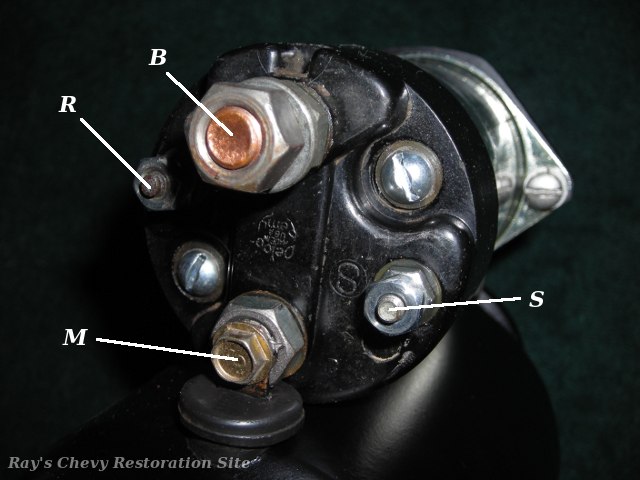

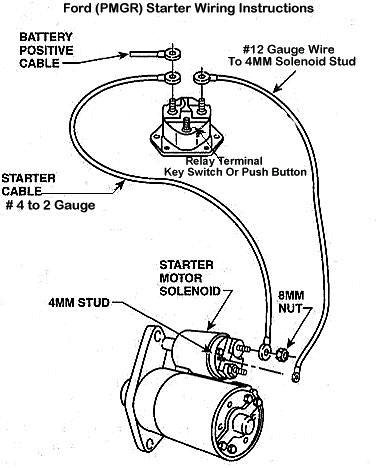

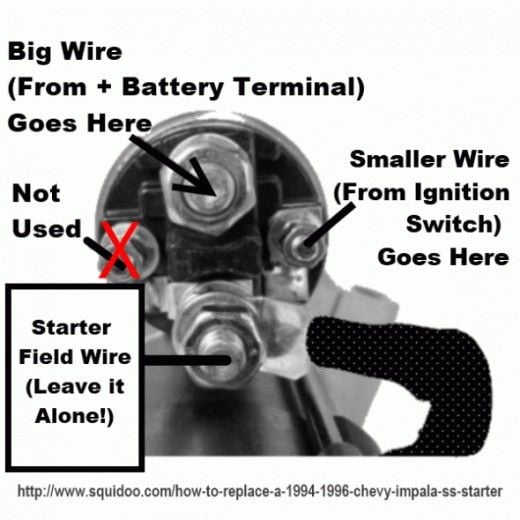

High torque starter wiring diagram. Use this diagram for wiring the starter to prevent starter solenoid 1 wire alternator contact welding for high torque competition engine starters. There is not a similar spade on the high torque unit other than one spade terminal which is also connected by external wire to the main feed postthe manufacturer says that my ignition switch connection should be connected to it but that effectively puts all wiresconnections to the same terminal. This starter is intended for use on gm corporate engines. C 2015 engine ground cable steel chassis starter gm 2 2 516 stud 10 stud s 12v lug 516 stud solenoid 38 bolt 516 stud 12 8 2 remo tsa wi ch optional starter sol ground neutral sw. It shows the components of the circuit as simplified shapes and the talent and signal links between the devices. 1 starter motor 2 mounting bolts 2 engine block shims.

66256 66258 66259 66266 66267. High torque starter wiring diagram wiring diagram is a simplified within acceptable limits pictorial representation of an electrical circuit. 1 housing shim. 1 solderless terminal. Hi torque mini starter mounting and wiring instructions wiring. Will wire the mini starter like the diagram below.

However if you discover that the engine dies the moment you turn the key from cranking position to run position then you need to disconnect the small black wire with the yellow stripe from the. Hi torque starter bypass wire this wire installs between the s post of single terminal hi torque starter and the post on the coil enabling the ignition system to receive voltage in the crank position when using an early non bussed ignition switch. Small and big block v 8 and.