Hadley air horn wiring diagram using 12 wrench disconnect horn air line from solenoid by loosening 12. Using 12 wrench disconnect horn air line from solenoid by loosening 12.

Omega Air Horn Wiring Diagram Diagram Base Website Wiring

Hadley air horn wiring diagram. And when combined with a hadley air compressor theyre the number one horn used on suvs 4 x 4s vans pickup trucks motor homes motorcycles and power sail boats. Using 12 wrench disconnect horn air line from solenoid by loosening 12 compression nut. When activated by a switch or button a valve opens allowing air to escape out of the compression chamber and into the base of the horn known as the throat. Verify there are no kinks in the nylon air tubing. Hadley is the worldwide leader in air horn systems. Youll see our horns used as original equipment on over the road tractortrailer rigs.

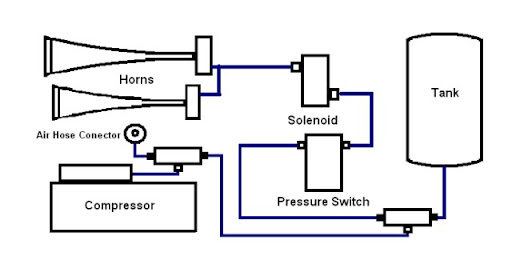

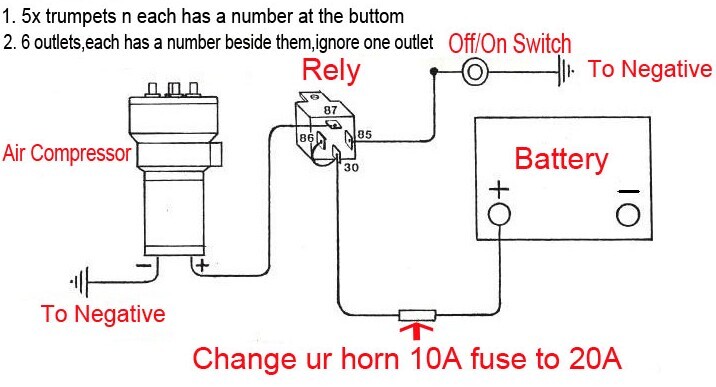

Removal of this fitting allows. How to wire air horns air horn install for automotive and marine use duration. If more than 4 minutes are required to. Lessco electronics 1299658 views. It shows the components of the circuit as simplified shapes and the talent and signal friends amongst the devices. Hadley air horn wiring diagram wiring diagram is a simplified standard pictorial representation of an electrical circuit.

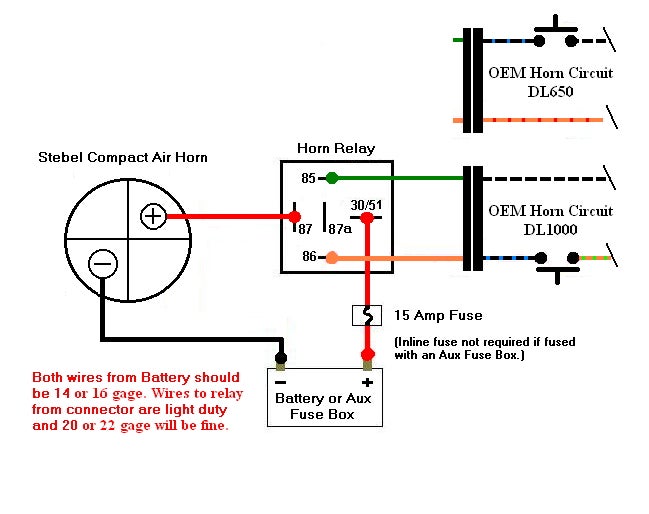

Youll see our horns used as original equipment on over the road tractortrailer rigs. If air is not coming out of the horn check to see if there is air pressure in the tank. Check that the solenoid has power minimum of 10vdc when the horn button is pushed. And when combined with a hadley air compressor theyre the number one horn used on suvs 4 x 4s vans pickup trucks motor homes motorcycles and power sail boats. With toggle switch in off position only the vehicles electric horn will operate. Air horn wiring diagram air horn wiring diagram air horn wiring diagram compressor air horn wiring diagram switch every electric structure is composed of various unique pieces.

Using 34 wrench loosen and remove brass outlet fitting that the air line was attached to. This chamber is kept pressurized to ensure the horn sounds instantly. Horn wire using a wire splice connector item37. As shown in schematic wiring mount toggle switch item34 on or under the dash. Compressor to be turned off to prevent it from running due to pressure drops in the air tank. Drain all air from tank.

Air horns work by using pressurized air to vibrate a diaphragm located within a compression chamber. Each component should be set and linked to other parts in particular manner. Otherwise the structure will not work as it should be. Compressor starts automatically when pressure drops below 110 psi. Hadley is the worldwide leader in air horn systems. With switch in on position air horns and electric horn will be operated.