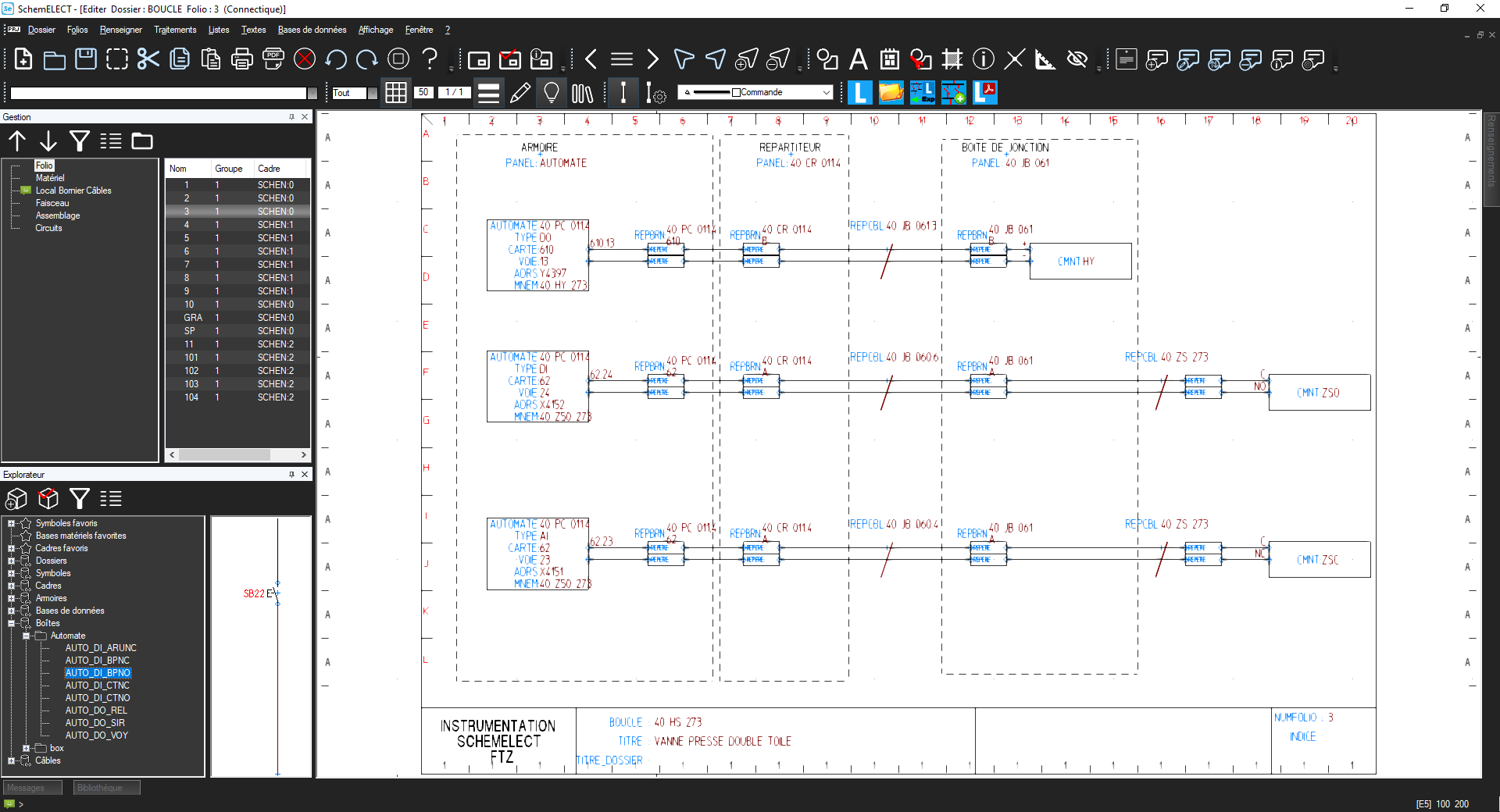

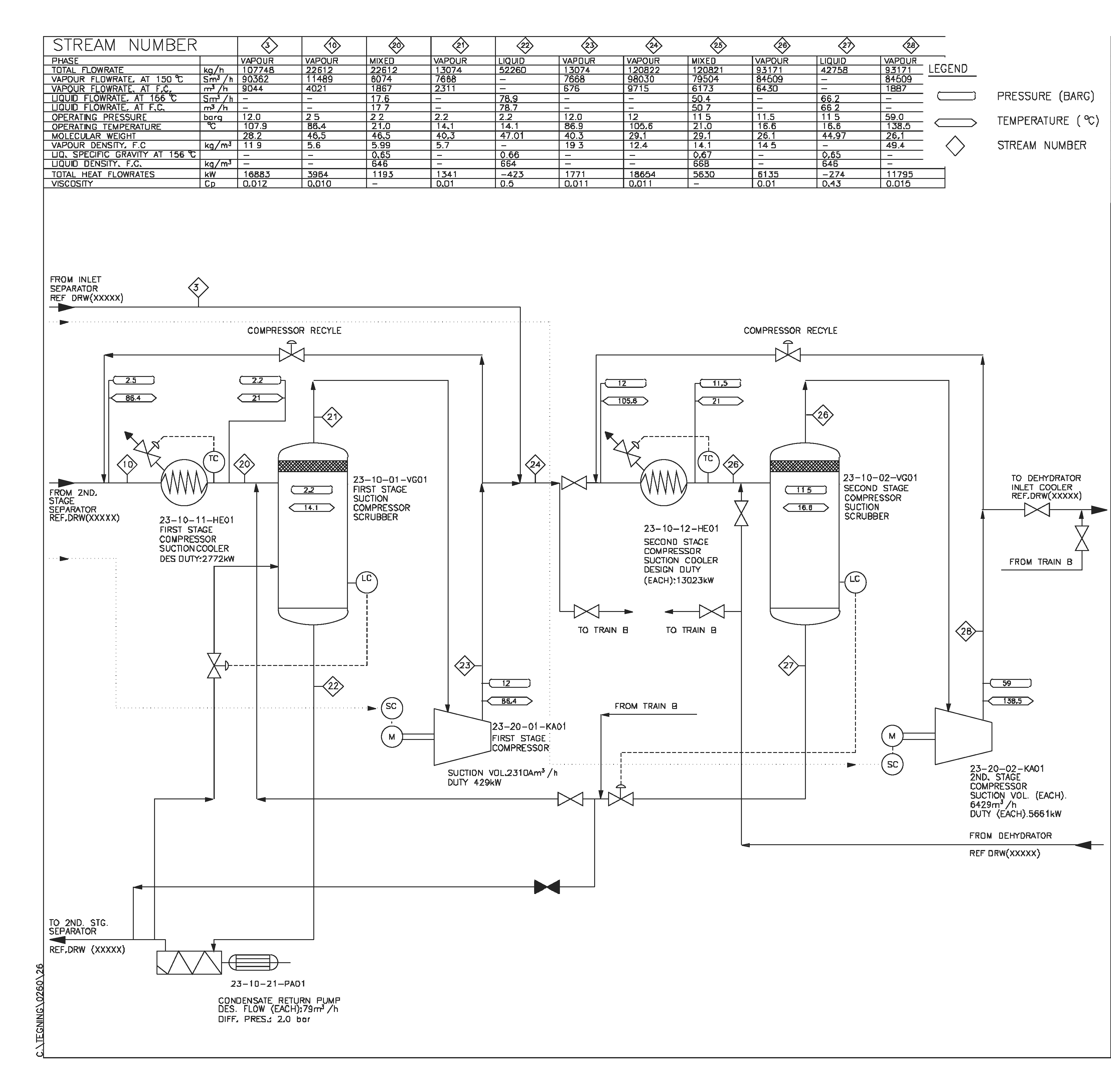

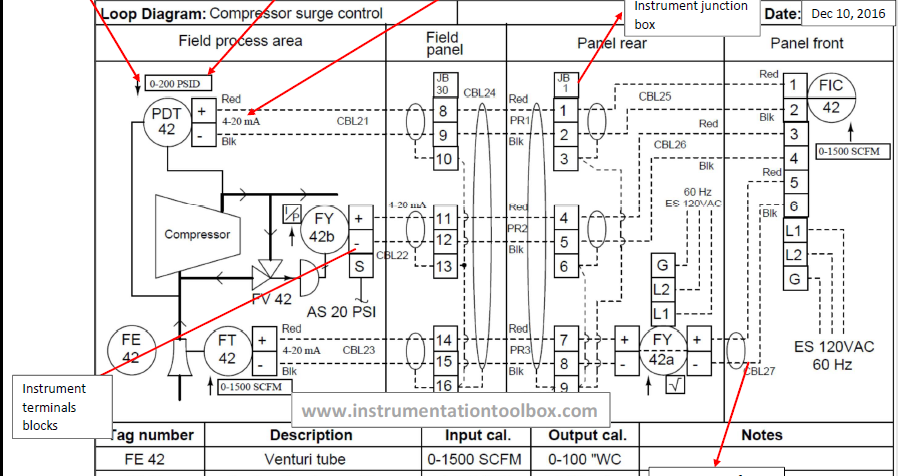

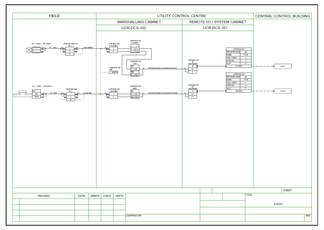

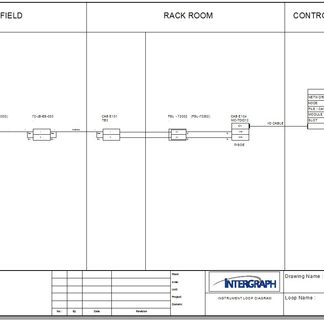

Pids and loop diagrams are construction and documentation drawings that depict the flow of the process and illustrate the instrumentation control and measurement interactions wiring and connections to the process. Vice versa fieldside is again divided into field area and junction box.

Piping And Instrumentation Diagram Wikipedia

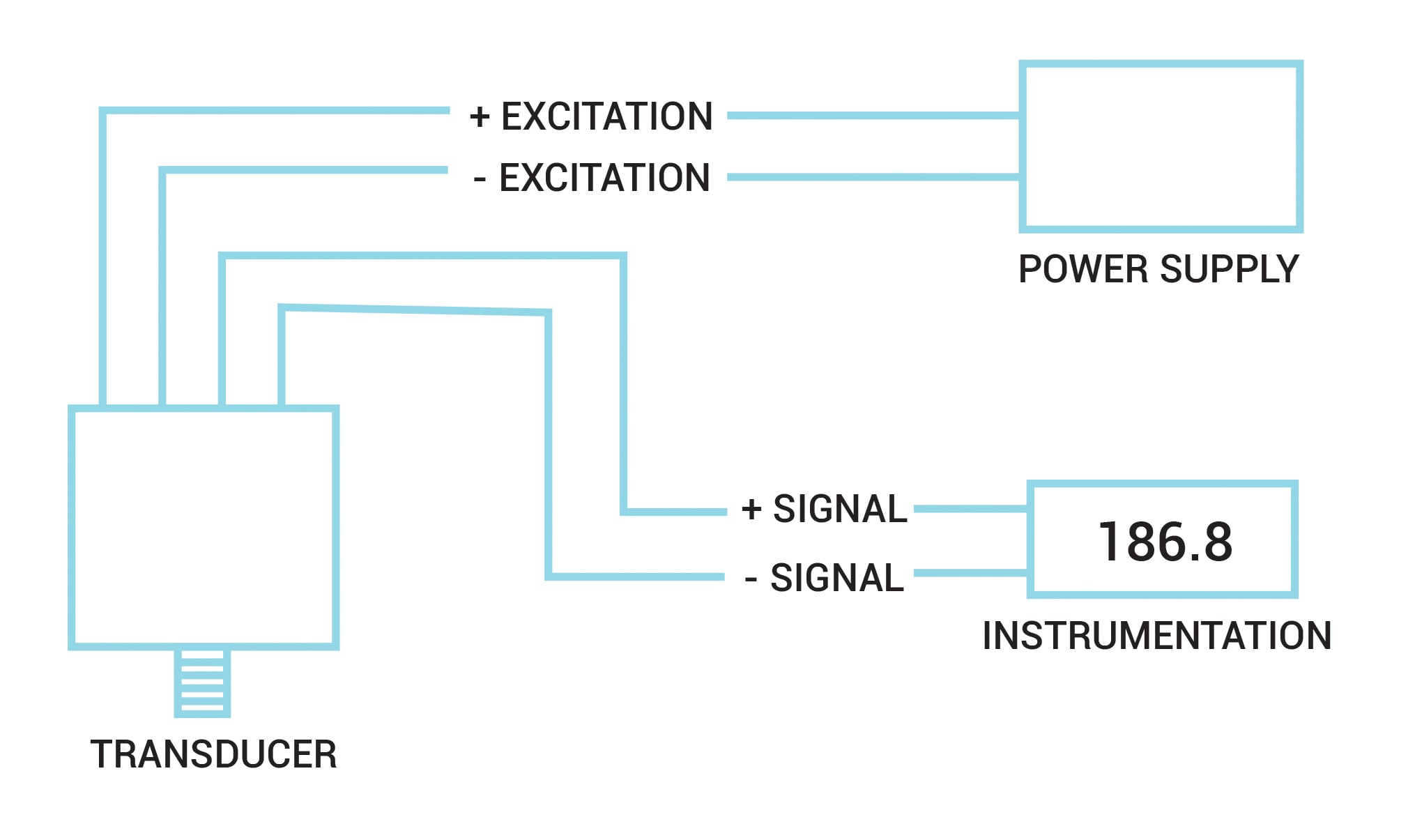

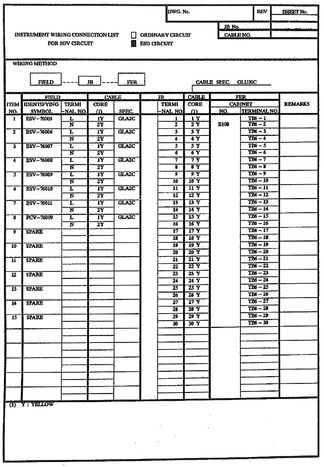

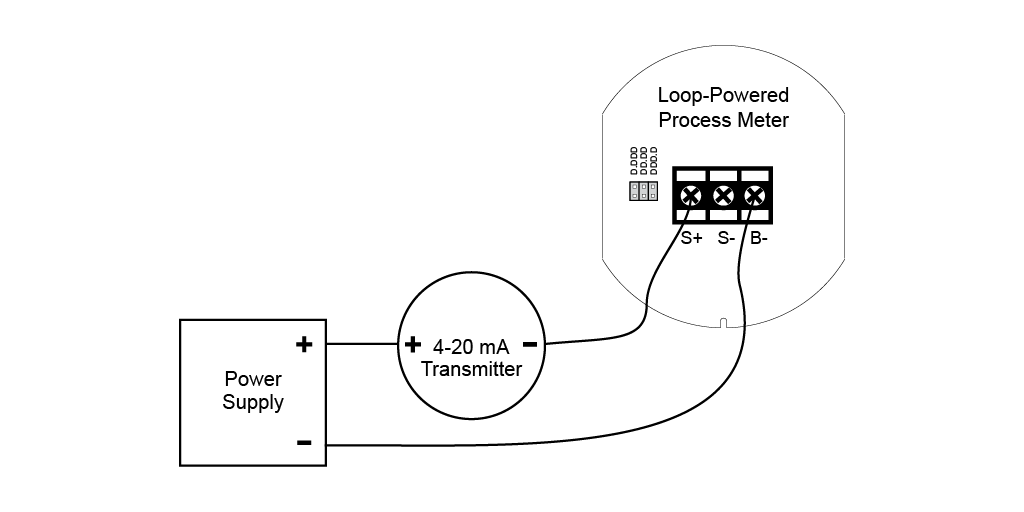

Loop wiring diagram instrumentation. In a 4 20ma current loop all the signalling current flows through all devices. And instrument tag ending with terminal numbers. One is the field side and other is control room side. Loop diagrams are fairly constrained in their layout as per the isa 51 standard. Instrument loop diagram ild represents a connection from the field instrument to control room. Vice versa instrument loop diagram is divided into two basic sections.

Basics of instrument loop diagrams they show all the instruments in a control loop each instrument bubble in a loop diagram represent an individual device with its own terminals for connecting wires. Tag the instrument wire following the instrument tag by adding and on the instrument side. When a loop diagram shows you exactly what wire color to expect at exactly what point in an instrumentation system and exactly what terminal that wire should connect to it becomes much easier to proceed with any troubleshooting calibration or upgrade task. The 4 20ma current loop is a very robust and popular sensor signalling standard. Find the top 15 loop diagram questions here. The process is illustrated in sections or subsystems of the process called loops.

Loop diagrams are fairly constrained in their layout as per the isa 51 standard. Dashed lines in instrument drawings represent individual copper wires rather than whole cables. Loop diagram helps us to read the wiring connections from field instruments to system cabinet. It is important to consider their value for design construction checkout start up operation maintenance rearrangement and reconstruction. When a loop diagram shows you exactly what wire color to expect at exactly what point in an instrumentation system and exactly what terminal that wire should connect to it becomes much easier to proceed with any troubleshooting calibration or upgrade task. Current loops are ideal for data transmission because of their inherent insensitivity to electrical noise.

Instrument loop diagrams are suitable for general use throughout industry. Benefits can include reduction in engineering costs.